Production Engineering

1

GATE ME 2025

Numerical

+1

-0

A liquid metal is poured in a mold cavity of size $200 \mathrm{~mm} \times 200 \mathrm{~mm} \times 200 \mathrm{~mm}$. The cooling is uniform in all directions with NO additional compensation for shrinkage. Considering the volumetric shrinkage during solidification and solid contraction as $7 \%$ and $8 \%$, respectively, the length of the cube edge after cooling down to the room temperature is ___________ mm (rounded off to 1 decimal place).

Your input ____

2

GATE ME 2024

MCQ (Single Correct Answer)

+1

-0.33

The allowance provided to a pattern for easy withdrawal from a sand mold is

3

GATE ME 2023

MCQ (More than One Correct Answer)

+1

-0

In a metal casting process to manufacture parts, both patterns and moulds provide shape by dictating where the material should or should not go. Which of the option(s) given correctly describe(s) the mould and the pattern?

4

GATE ME 2022 Set 2

MCQ (Single Correct Answer)

+1

-0.33

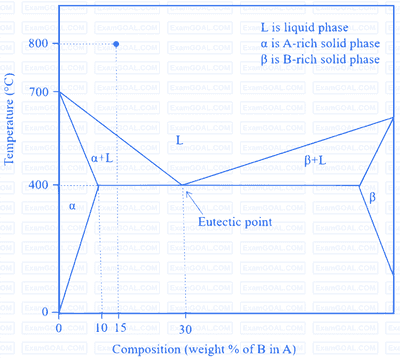

Fluidity of a molten alloy during sand casting depends on its solidification range. The phase diagram of a hypothetical binary alloy of components A and B is shown in the figure with its eutectic composition and temperature. All the lines in this phase diagram, including the solidus and liquidus lines, are straight lines. If this binary alloy with 15 weight % of B is poured into a mould at a pouring temperature of 800 °C, then the solidification range is

Questions Asked from Marks 1

GATE ME 2025 (1) GATE ME 2024 (1) GATE ME 2023 (1) GATE ME 2022 Set 2 (3) GATE ME 2016 Set 1 (1) GATE ME 2016 Set 3 (1) GATE ME 2016 Set 2 (1) GATE ME 2015 Set 3 (1) GATE ME 2014 Set 3 (2) GATE ME 2013 (1) GATE ME 2011 (1) GATE ME 2009 (1) GATE ME 2007 (1) GATE ME 2006 (1) GATE ME 2004 (1) GATE ME 2003 (1) GATE ME 2002 (2) GATE ME 2001 (1) GATE ME 2000 (1) GATE ME 1999 (1) GATE ME 1996 (1) GATE ME 1993 (1) GATE ME 1992 (1) GATE ME 1991 (2) GATE ME 1990 (1) GATE ME 1989 (2) GATE ME 1988 (1) GATE ME 1987 (1)

GATE ME Subjects

Engineering Mechanics

Machine Design

Strength of Materials

Heat Transfer

Production Engineering

Industrial Engineering

Turbo Machinery

Theory of Machines

Engineering Mathematics

Fluid Mechanics

Thermodynamics

General Aptitude