Production Engineering

1

GATE ME 2006

MCQ (Single Correct Answer)

+2

-0.6

In an orthogonal machining operation:

$$\,\,\,\,\,\,\,\,\,\,$$Uncut thickness $$\,\,\,\,\,$$ $$= 0.5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting speed $$\,\,\,\,\,\,\,\,\,\,$$ $$= 20$$ $$m/min$$

$$\,\,\,\,\,\,\,\,\,\,$$Width of cut $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Chip thickness $$\,\,\,\,\,\,\,\,$$ $$= 0.7$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Thrust force$$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting force $$\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 1200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Rake angle $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$ = {15^ \circ }$$

Assume Merchant’s theory

$$\,\,\,\,\,\,\,\,\,\,$$Uncut thickness $$\,\,\,\,\,$$ $$= 0.5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting speed $$\,\,\,\,\,\,\,\,\,\,$$ $$= 20$$ $$m/min$$

$$\,\,\,\,\,\,\,\,\,\,$$Width of cut $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Chip thickness $$\,\,\,\,\,\,\,\,$$ $$= 0.7$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Thrust force$$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting force $$\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 1200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Rake angle $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$ = {15^ \circ }$$

Assume Merchant’s theory

The values of shear angle and shear strain, respectively are

2

GATE ME 2006

MCQ (Single Correct Answer)

+2

-0.6

In an orthogonal machining operation:

$$\,\,\,\,\,\,\,\,\,\,$$Uncut thickness $$\,\,\,\,\,$$ $$= 0.5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting speed $$\,\,\,\,\,\,\,\,\,\,$$ $$= 20$$ $$m/min$$

$$\,\,\,\,\,\,\,\,\,\,$$Width of cut $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Chip thickness $$\,\,\,\,\,\,\,\,$$ $$= 0.7$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Thrust force$$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting force $$\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 1200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Rake angle $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$ = {15^ \circ }$$

Assume Merchant’s theory

$$\,\,\,\,\,\,\,\,\,\,$$Uncut thickness $$\,\,\,\,\,$$ $$= 0.5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting speed $$\,\,\,\,\,\,\,\,\,\,$$ $$= 20$$ $$m/min$$

$$\,\,\,\,\,\,\,\,\,\,$$Width of cut $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 5$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Chip thickness $$\,\,\,\,\,\,\,\,$$ $$= 0.7$$ $$mm$$

$$\,\,\,\,\,\,\,\,\,\,$$Thrust force$$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Cutting force $$\,\,\,\,\,\,\,\,\,\,\,\,$$ $$= 1200$$ $$N$$

$$\,\,\,\,\,\,\,\,\,\,$$Rake angle $$\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,$$ $$ = {15^ \circ }$$

Assume Merchant’s theory

The coefficient of friction at the tool chip interface is

3

GATE ME 2005

MCQ (Single Correct Answer)

+2

-0.6

Two tools $$P$$ and $$Q$$ have signature $${5^ \circ } - {5^ \circ } - {6^ \circ } - {6^ \circ } - {8^ \circ } - {30^ \circ } - 0$$ and $${5^ \circ } - {5^ \circ } - {7^ \circ } - {7^ \circ } - {8^ \circ } - {15^ \circ } - 0$$ (both $$ASA$$) respectively. They are used to turn components under the same machining conditions. If $${h_p}$$ and $${h_Q}$$ denote the peak-to-valley height of surfaces produced by the tools $$P$$ and $$Q$$, the ratio $${h_P}/{h_Q}$$ will be

4

GATE ME 2005

MCQ (Single Correct Answer)

+2

-0.6

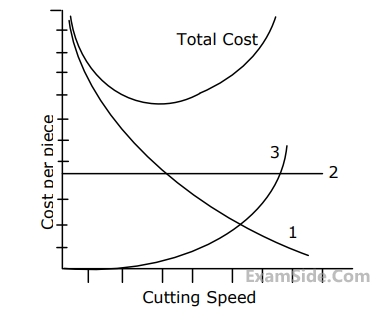

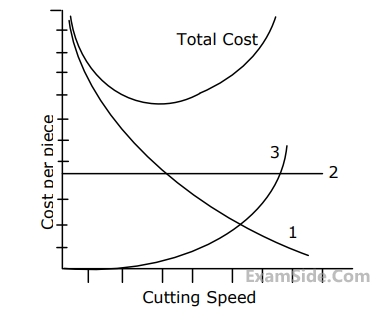

The figure below shows a graph, which qualitatively relates cutting speed and cost per piece produced.

The three curves $$1,2$$ and $$3$$ respectively represent

Questions Asked from Marks 2

GATE ME 2024 (1) GATE ME 2023 (3) GATE ME 2022 Set 2 (2) GATE ME 2022 Set 1 (2) GATE ME 2017 Set 2 (2) GATE ME 2017 Set 1 (1) GATE ME 2016 Set 1 (1) GATE ME 2016 Set 3 (2) GATE ME 2016 Set 2 (1) GATE ME 2015 Set 2 (1) GATE ME 2015 Set 1 (1) GATE ME 2015 Set 3 (1) GATE ME 2014 Set 1 (1) GATE ME 2014 Set 4 (1) GATE ME 2014 Set 3 (1) GATE ME 2013 (3) GATE ME 2011 (1) GATE ME 2010 (1) GATE ME 2009 (2) GATE ME 2008 (3) GATE ME 2007 (5) GATE ME 2006 (3) GATE ME 2005 (2) GATE ME 2004 (1) GATE ME 2003 (1) GATE ME 2001 (2) GATE ME 2000 (1) GATE ME 1999 (1) GATE ME 1998 (1) GATE ME 1997 (2) GATE ME 1989 (1) GATE ME 1988 (1)

GATE ME Subjects

Engineering Mechanics

Machine Design

Strength of Materials

Heat Transfer

Production Engineering

Industrial Engineering

Turbo Machinery

Theory of Machines

Engineering Mathematics

Fluid Mechanics

Thermodynamics

General Aptitude